If you look into various local markets

today, you can realize that plastic bags have replaced the use of

materials such as metal, wood, paper etc. And this is really good that

it has happened. Plastics are relatively very cheap and light in weight,

which has lifted up the use of plastics to that level. As a business

person, if you have a shop, selling certain things in local markets,

then you can use plastic bags to allow your customers to carry their

stuff to their home without dropping it on streets.

However,

the use of plastics is not limited to bags only. You can find other

things made up of plastics which you can use to support your business.

Below I have listed about 3 usable plastic products, which I am sure

will help you in business. Have a look!

Bottle or Fruit Crate –

Bottle

or Fruit Crate is nothing but a kind of container that is used to

preserve the bottle or fruit respectively. The purpose of such

containers is not limited to preserving stuffs in the stores, these are

also found to be very helpful in terms of transporting from one place to

another without braking/ damaging anything.

Plastic Table and Chairs –

Of course, days are gone when people were using woods and steels to build tables and chairs. Nowadays, by the help of various types plastic moulds,

you can have flexible table and chair designs. However, the best things

about these types are - they are durable, lighter in weight, do not

require any maintenance and even cost very low price.

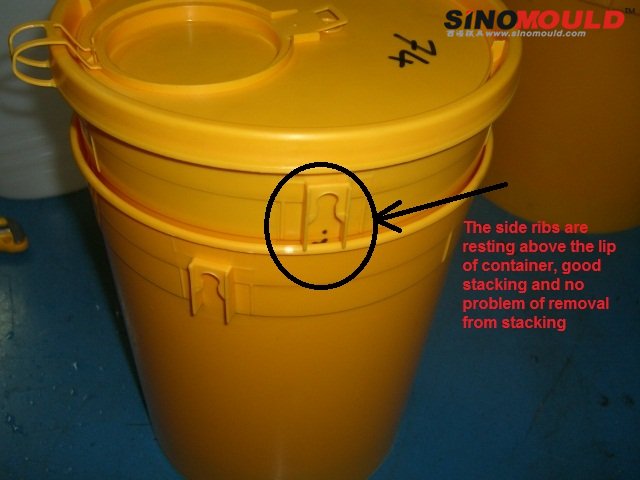

Dustbin –

The

use of plastic dustbin is very regular in the local markets. They not

only can help you to keep surrounding neat and clean but also can help

you to give your customers a reason to come back to your store again and

again for this reason.